What is carpet dyeing?

Carpet dyeing is a process in which carpet fibers are colored by a dye material that can be chemical or natural based. In this process, the desired fibers are placed in the vicinity of the dye at a certain temperature and for a certain period of time. A dye material is a substance capable of dyeing fibers and textiles. When the dye material comes into contact with the fibers, the dye molecules are released and penetrate deep into the fibers, and as a result, a strong bond is established between them. Dyeing is a practice for which one must acquire high knowledge and skills.

Natural dyeing

What things are important for dyeing?

Dye Material

One of the factors affecting dyeing is the type of dye used in this process. There are different types of dyes, most of which have a good tendency to be absorbed by wool. According to the type of fiber, the dyer chooses the appropriate dye. In fact, it is the type of fiber that determines what type of color is needed.

Natural colors

Wool is a type of protein fiber that is obtained from sheep and has a natural structure, so it is natural to use colors that have a similar structure and are somehow natural. In general, 3 types of methods are used in dyeing of carpet fiber , which are: vegetable dyes, animal dyes, and metal dyes. The mentioned colors are in the category of natural colors.

Red and golden acer trees for natural dyeing

Aniline dyes

There are other types of dyes that are chemical in nature. Aniline and chrome dyes are part of this category. Aniline dyes are not stable against light and water in any way, and only because of their cheap price and transparency, as well as ease of use, they were used in a relatively large amount in dyeing workshops at the beginning.

Aniline color

Chrome dyes

But chrome colors are more stable than aniline colors and give a uniform color to your carpets, but in any case, they are chemical colors and do not give the carpets a natural look.

Chrome color

Another factor that determines the type and quality of the used coloring agent is the use of the product in the future. For example, a hand-woven carpet is a product that is washed many times during the period of time it is used. Therefore, dyes should be used that have the maximum stability when washing the carpet and also preserve its color to some extent when exposed to sunlight.

Fibers

Another important thing to pay attention to in the dyeing process is the quality and type of fibers that are dyed. For this reason, it is possible that two skeins of thread that have different qualities, if dyed in the same way, the result will be different. The better the quality of the fibers, the better the result will be.

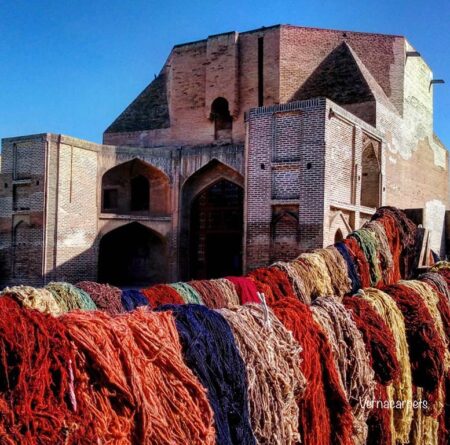

Colorful spring at Heydarieh Qazvin school

Dye pot

In the case of carpet dyeing with dyes, choosing a dyeing pot is very important. A pot is a container in which fibers are placed for dyeing. The material of this container should be steel or copper and it should be resistant to temperature. Rotability and proportionality of the size of the pot with the volume of fibers to be dyed are other parameters that should be taken into consideration when choosing a dyeing pot.

Dyeing pots

Water

The water used for dyeing is not ordinary water! Using the right water is the most important reason for the transparency of the color on the fibers. If water containing calcium and magnesium salts is used for dyeing, it causes the color of the fibers to become dull. Therefore, the use of water hardness methods in dyeing workshops is very important.

Heat

You need heat to increase the dyeing speed and improve the color quality. A skilled dyer, in addition to mastering the gradual addition of dyeing materials, must also master the heat control of dyeing pots. One of the problems of using traditional pots is that the temperature is not the same in different parts.

Secondary materials

Secondary materials in dyeing refers to materials that play a key role in the dyeing process and without them this process is incomplete. The quality of secondary materials in dyeing is very important and the use of poor quality materials will bring unfavorable results. Some secondary materials are used as hardeners to soften water. Some of them help to make colors uniform and Some increase the speed of dyeing. Among the secondary materials, we can mention alum, limewater, sulfuric acid and lactic acid in yogurt and dough.

White alum

Agitator

It is a device that is used to stir the fibers inside the pot, and the material of the stirrer must be wooden.

In the following, we will examine in detail both types of carpet dyeing methods, i.e. traditional and industrial dyeing, and we will introduce them to you.

Also read: What are natural carpets?

How to dye wool fibers?

In general, dyeing of carpet is done in two traditional and industrial ways:

Traditional dyeing steps

In this method, dyeing is done in large copper pots. The heat of these pots is provided by the fire flame. The wool is placed inside these pots in an unspun form. The first step of traditional dyeing is soaking the fibers. At this stage, the skeins are poured into water with a temperature of 30 to 40 degrees and they are allowed to soak in the pot for two hours. Then they take out the skeins and take the water and wash them again in water with a temperature of 30 to 35 degrees with detergent to remove pus and fat. It is separated from the fibers. Then they take the water again and let it dry in front of the sun.

Traditional dyeing workshop in Zanjan

The next step is to add the secondary substance. In this step, the pot is filled with water and heated to 70 degrees. Then the secondary substance is poured into the pot. The secondary substance should stay in the pot for about 20 minutes. After that, the pre-washed and dried skeins are placed in the boilers containing the secondary material and the temperature is increased to 80 degrees. In the next step, the skeins are placed in the boilers containing the dye and allowed to boil in the pot for one hour. The first step is to stir the fibers well with a stirrer so that the color penetrates deep into the fibers. After an hour, the skeins are ready. You must allow them to cool.

If dyes and secondary substances are added to the pot at the same time, this mixture should remain in the pot for one day, then after 24 hours, the wool fibers are taken out and washed.

Industrial dyeing steps

In industrial dyeing, the used fibers must first be washed well before dyeing so that no fat or pus remains on them. This washing is done by special industrial soaps. Unlike traditional dyeing, all the steps in industrial dyeing are mechanized and done by machines. First, the washed fibers are loosely wrapped around the perforated bobbins and placed in the baskets. Proper distance must be observed between the bobbins so that they do not stick together.

At this stage, the bobbins are ready to pour the dyeing materials. These containers are placed inside the steam pots. Tanks are connected to the steam pots, one of which transfers water and the other the dye substance into the pot. Dyeing temperature for wools It is between 45 and 50 degrees Celsius, which may reach 100 degrees during dyeing.

Industrial dyeing workshop in Golestan province

This operation lasts up to an hour, and after that, water is added to the pot until the temperature of the fibers reaches 75 degrees and they do not lose their color. Cold water enters the pot through pipes, and the water itself leaves the pot. These fibers are washed with cold water for 15 minutes. Ammonia is also used to stabilize the colors. Ammonia has an alkaline property that destroys the fibers. At this stage, you must use an acidic substance to make the fibers neutral.

Industrial dyeing pot

Finally, the fibers are washed again with cold water so that the acid does not remain on the fibers, and then the bobbins are placed in the dryers. The process of drying the fibers takes about 4 hours. Then the fibers are tightly twisted and heated for 30 minutes to remove their twisted state. At this stage, the fibers are completely ready.

Final word

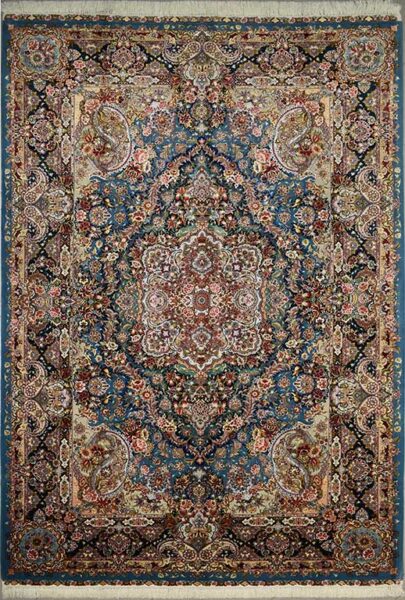

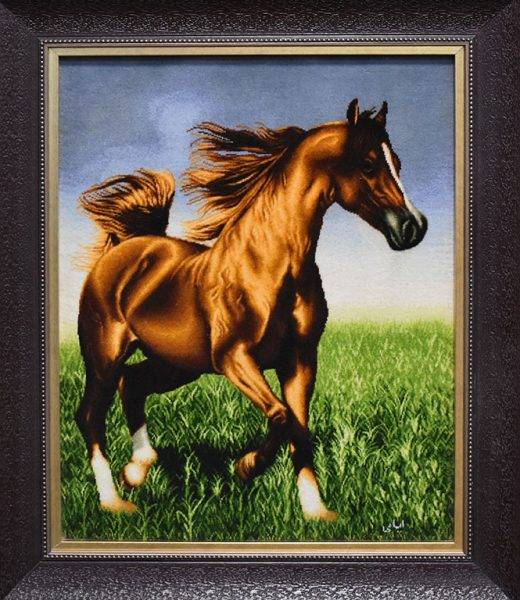

Carpet dyeing is definitely one of the most important factors that give special beauty to handwoven carpets. In this article, we introduced you to the definition of dyeing and the types of traditional and industrial dyeing. Regardless of all the above factors, it is the skill and mastery of the dyer that plays a vital role in the quality of dyeing. The dyer must have complete knowledge of the characteristics of fibers, dyestuffs and dyeing pots. Some carpets do not have the necessary brightness despite the use of high-quality colors. Here, the issue of dyer’s skill and lack of color penetration into the fibers is raised. If the dyeing process is not done correctly, the molecules cannot penetrate the fibers properly and the carpet will have a dull appearance.

3 thoughts on “Dyeing of handwoven carpet and traditional and industrial methods”